From ancient times to the present day, the evolution of construction methods is a testament to human ingenuity and the relentless pursuit of progress. From the use of mud bricks and wooden beams to the implementation of steel frames and concrete, the methods and materials have evolved dramatically, paving the way for sustainable housing solutions that cater to modern needs without compromising the environment.

MDCC TECH emerges as a pivotal force, steering the construction industry towards a future where technology enhances every aspect of building design, efficiency, and sustainability, with a keen focus on Pre-Engineered Buildings (PEBs) in constructing Filipino housing projects that reflect the unique cultural and environmental considerations of the region.

Historical Context and Traditional Construction

Historically, construction relied heavily on local materials and manual labor. Techniques were passed down through generations, with innovations often spurred by necessity or the discovery of new materials.

However, these marvels of engineering were limited by the era’s technological capabilities, requiring immense human effort and decades, if not centuries, to complete.

The Industrial Revolution to the Information Age

The Industrial Revolution marked a significant turning point, introducing machinery that began to automate some construction processes. The 20th century saw further advancements with the development of power tools, cranes, and the introduction of synthetic materials, such as plastics and composites.

The Information Age brought about computer-aided design (CAD) and building information modeling (BIM), revolutionizing planning and design by increasing precision and reducing errors. This era has also seen a heightened focus on Pre-Engineered Buildings (PEBs) as a solution to the growing need for sustainable housing in the Philippines and around the world.

Contemporary Technological Advancements

Today, the construction industry is on the cusp of a new era, fueled by advancements such as 3D printing, autonomous construction vehicles, and smart building technologies. These tools not only improve the speed and efficiency of construction projects but also enhance safety and sustainability.

Modular construction and prefabrication methods reduce waste and allow for tighter quality control, signaling a shift towards more environmentally conscious building practices.

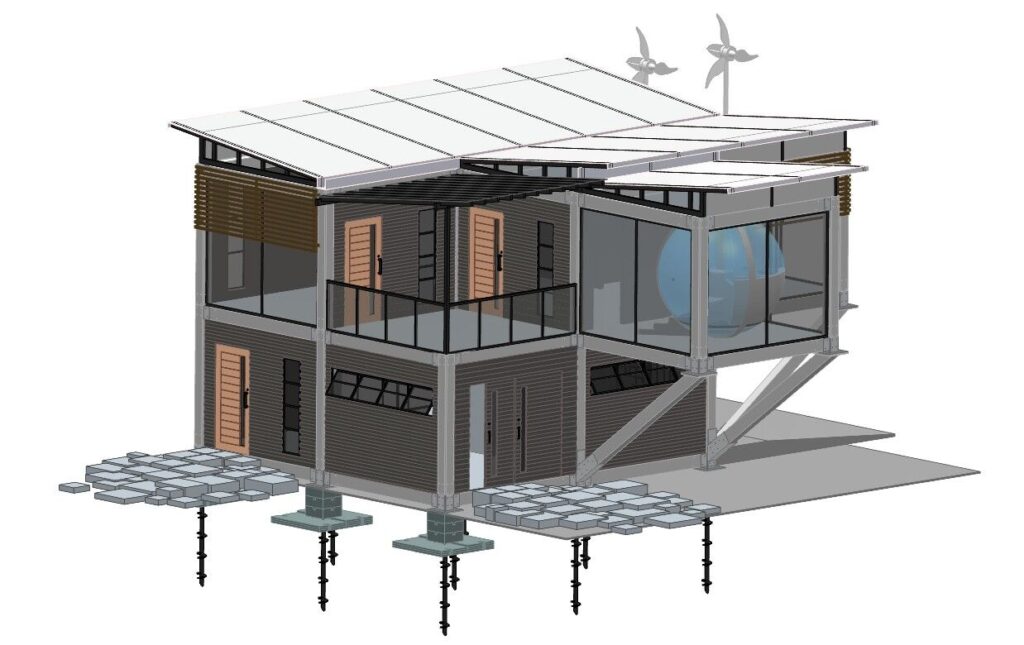

MDCC TECH stands at the forefront of this transformation, pioneering solutions that embody the transition from traditional methods to a technology-driven approach. Their emphasis on Pre-Engineered Buildings (PEBs) and Assemble To Order (ATO) technology showcases a commitment to innovation. PEBs, with components manufactured off-site and assembled on-site, streamline the construction process, reduce costs, and minimize environmental impact. ATO technology further exemplifies MDCC TECH’s vision, offering a customizable approach to construction that leverages advanced manufacturing techniques for optimal efficiency and flexibility.

MDCC TECH is also able to tackle complex challenges, such as reducing the carbon footprint of buildings and enhancing their energy efficiency. Their approach signifies a paradigm shift in how buildings are conceived, designed, and constructed, promising a future where structures are not only built faster and more cost-effectively but are also more in harmony with the environment.

Final Thoughts

In the journey from ancient construction to the present, MDCC TECH is a pivotal force shaping a tech-driven future. Their focus on Pre-Engineered Buildings (PEBs) and innovative Assemble To Order (ATO) technology demonstrates a commitment to efficiency, sustainability, and flexibility. As construction enters a new era with 3D printing and smart technologies, MDCC TECH leads the way, envisioning a future where buildings are not only constructed faster and cost-effectively but also align with environmental harmony.

For more insights into our groundbreaking construction solutions and to discover how MDCC TECH is shaping the future of the construction industry, contact us today!